Is a professional manufacturer engaged in the research, development, production, sale and service of all kinds of food machinery and supporting machinery production line,fruit and vegetable cleaning equipment,frying equipment

The equipment is our company in accordance with the latest national GMP standard design and development of the latest canning machine, the machine applies the latest technology, design more reasonable, more concise, more solid.

The equipment is our company in accordance with the latest national GMP standard design and development of the latest canning machine, the machine applies the latest technology, design more reasonable, more concise, more solid.

The production line supporting the machine in addition to specify the material are stainless steel, all the machinery structure are selected in accordance with food hygiene standards.

The production line supporting the machine in addition to specify the material are stainless steel, all the machinery structure are selected in accordance with food hygiene standards.

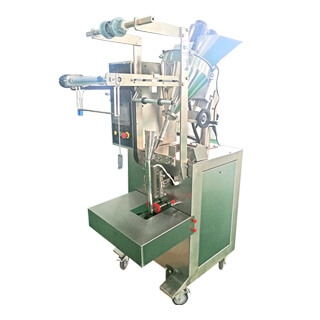

This machine is equipped with a dual-CPU microcomputer control system, a 5-inch LCD display in Chinese or English, a humanized operation interface, automatic cursor detection and tracking, and simpler operation. Equipped with a high-precision stepping motor to ensure the accuracy of the cutting position of each packaging bag.

This machine is equipped with a dual-CPU microcomputer control system, a 5-inch LCD display in Chinese or English, a humanized operation interface, automatic cursor detection and tracking, and simpler operation. Equipped with a high-precision stepping motor to ensure the accuracy of the cutting position of each packaging bag.

PLC control with stable reliable biaxial high accuracy output and color touch screen, bag-making, measuring, filling, printing,cutting , finished in one operation.

PLC control with stable reliable biaxial high accuracy output and color touch screen, bag-making, measuring, filling, printing,cutting , finished in one operation.

Applicable scope for packaging milk powder, sesame paste, strong bone powder, condiments, Ganoderma lucidum powder, granules and other items.

Applicable scope for packaging milk powder, sesame paste, strong bone powder, condiments, Ganoderma lucidum powder, granules and other items.

Suitable for quantitative filling of various bottles, cans and bags,Photoelectric induction blanking, or optional foot switch blanking,Feedback scale and indexing value can be adjusted to meet various accuracy requirements.

Suitable for quantitative filling of various bottles, cans and bags,Photoelectric induction blanking, or optional foot switch blanking,Feedback scale and indexing value can be adjusted to meet various accuracy requirements.

Zhengzhou HongLe Machinery Equipment Co., Ltd., established in 2011, is a professional manufacturer engaged in the research, development, production, sale and service of all kinds of food machinery and supporting machinery production line,fruit and vegetable cleaning equipment,meat equipment, frying equipment.We are located in Zhengzhou with convenient transportation access. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction.In addition, we have obtained CE certificates.Purchased from world-renowned manufacturers. Selling well in all cities and provinces around China, our products are also exported to clients in such countries and regions as Europe, North America, Southeast Asia, Africa, South America, South Korea .And received good feedback from most clients .

Learn MoreAccording to our market and our customer’s requirement,we are continuously in researching,developing and improve ourselves.

Our team is capable to provide abroad installation service,every technician is specialized to install equipment,teach and train customer’s stuff and remind equipment routine maintenance tips.

Once production list submit to production depart,quality and lead time guaranteed under rule components purchasing and production lines cooperating works.

Confirm machine with customer through accurate design drawing and layout drawing,ensure customer knows how machines will be and where to be placed in his factory and workshop.

We customize the powder filling machine production line for our USA customer. ltisuetforfling Potn power xyfrol and sugar nthe pouction lie , he powder can be ransfered fom the hopper tankc to the filing machine by the screw conveyor . The screw conveyor can be customize according to your height requirement. The powder iling machine is touch scren , i is convenient for operating.

Full automatic bottle powder filling production line ,include rotary bottle feeding machine,automatic powder feeding machine,automatic powder filling Machine,capping Machine,you can also choose labeling machine/inkjet printer/bottle aluminum foil sealing Machine.

Automatic capping machine is mainly suitable for different material specifications and different specifications of the cover, spin (rolling) cover. Suitable for screw cover, anti theft cover, child proof cover, press in cover, etc.

This machine can assemble all kinds of syring-es, including luer slip type, luer lock type and partial head type etc. Loading and assembling all the parts of the syringe automatically.Mitsubishi converter, microprocessor controland photoelectric monitoring has been adopt-ed, therefore it has such features as stops auto-matically without materials and starts automati-cally when supplementing the materials. Highspeed of assembling and stable performance.No pollution for products and purification workshop, able to work continuously for 24hours.

Full automatic filling production line ,include bottle table ,wind feeding bottle,three-in-one function filling machine, top cover machine, outer bottle delivery .Our Engineer designed the tomato paste filling and capping production line.

This machine can seal the valves and fill gas in the cans,it is suitable for customers who just need to fill gas in the cans or who fill the liquid in the cans manually.

Semi Automatic powder filling machine ( LCD touch screen) were shipped to Dominican Republic , which used for filling various powder.

Automatic High Speed Multi-Function Pillow Type Packaging Machine were shipped to Singapore , which used for packing bread .